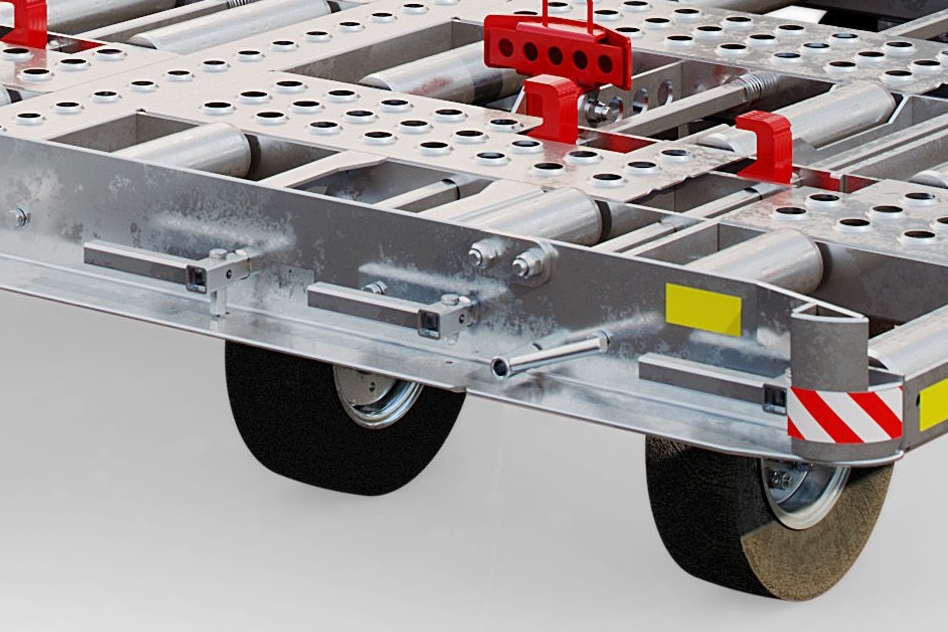

Knowing, that the approach of service staff to the airport equipment is not always light-handed, we designed our dollies to withstand the challenging operating conditions as long as possible. We used high-grade steel, reinforced the chassis by lots of structural welding and used the highest-quality components from renowned manufacturers as the Continental solid rubber wheels, Jost turntables and Rockinger automatic rear coupling device with theft-protection in addition. A matter of course being also the quality galvanised conveyor rollers and a durable, hot-dip galvanised frame. Parking brake is standardly activated by the raising of towbar and its automatic latching in vertical position can be simply released by a foot pedal thereafter.

Besides robustness, we did not forget to equip our dollies with smart solutions, that make the manipulation easier and quicker or significantly save the transport and service costs.

Key features:

The KCT2000 type container dolly is characterised by the 360° rotatable upper platform with a 90° latching. It is also equipped with a sophisticated container locking, which automatically folds down at container loading as well as automatically locks the container in upon reaching the correct position. The container locks and the platform rotation latching are released ergonomically by a foot pedal. The dolly also includes a hand-operated stop for the transportation of the LD2 container type. The parking brake acts on the front axle wheels.

Options:

-zapadka_3to2.jpg) For convenient and safe container transportation. At loading, the stop folds down automatically and when unloading, using a foot pedal you release the stop on the opposite side so that you can easily push the container out of the dolly.

For convenient and safe container transportation. At loading, the stop folds down automatically and when unloading, using a foot pedal you release the stop on the opposite side so that you can easily push the container out of the dolly.

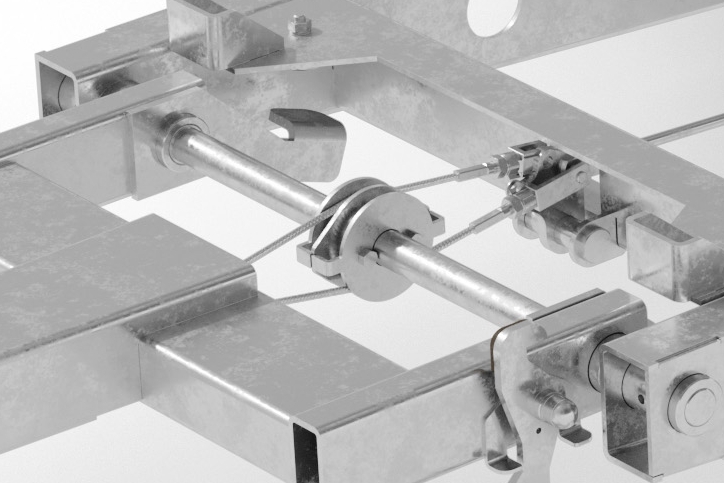

Automatic latching at 90° positions. Latch release by the means of convenient foot pedal.

Automatic latching at 90° positions. Latch release by the means of convenient foot pedal.

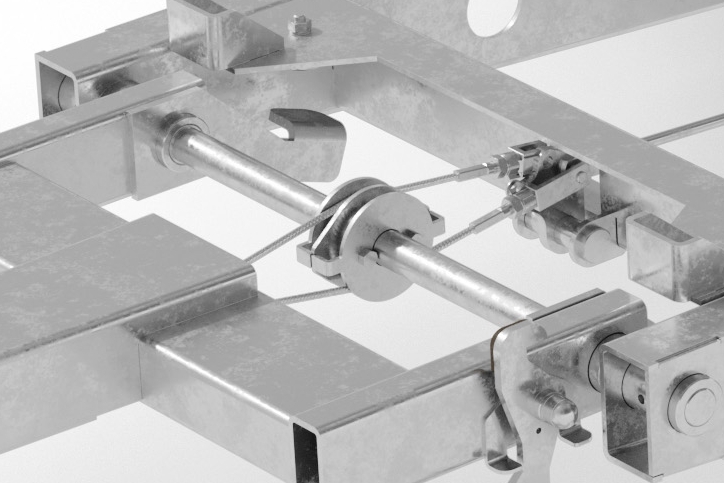

In addition to standard braking by raising the towbar, the brake is - for enhanced security - also activated in the case when unhitched towbar is lowered to the ground by its own weight.

In addition to standard braking by raising the towbar, the brake is - for enhanced security - also activated in the case when unhitched towbar is lowered to the ground by its own weight.

Key features:

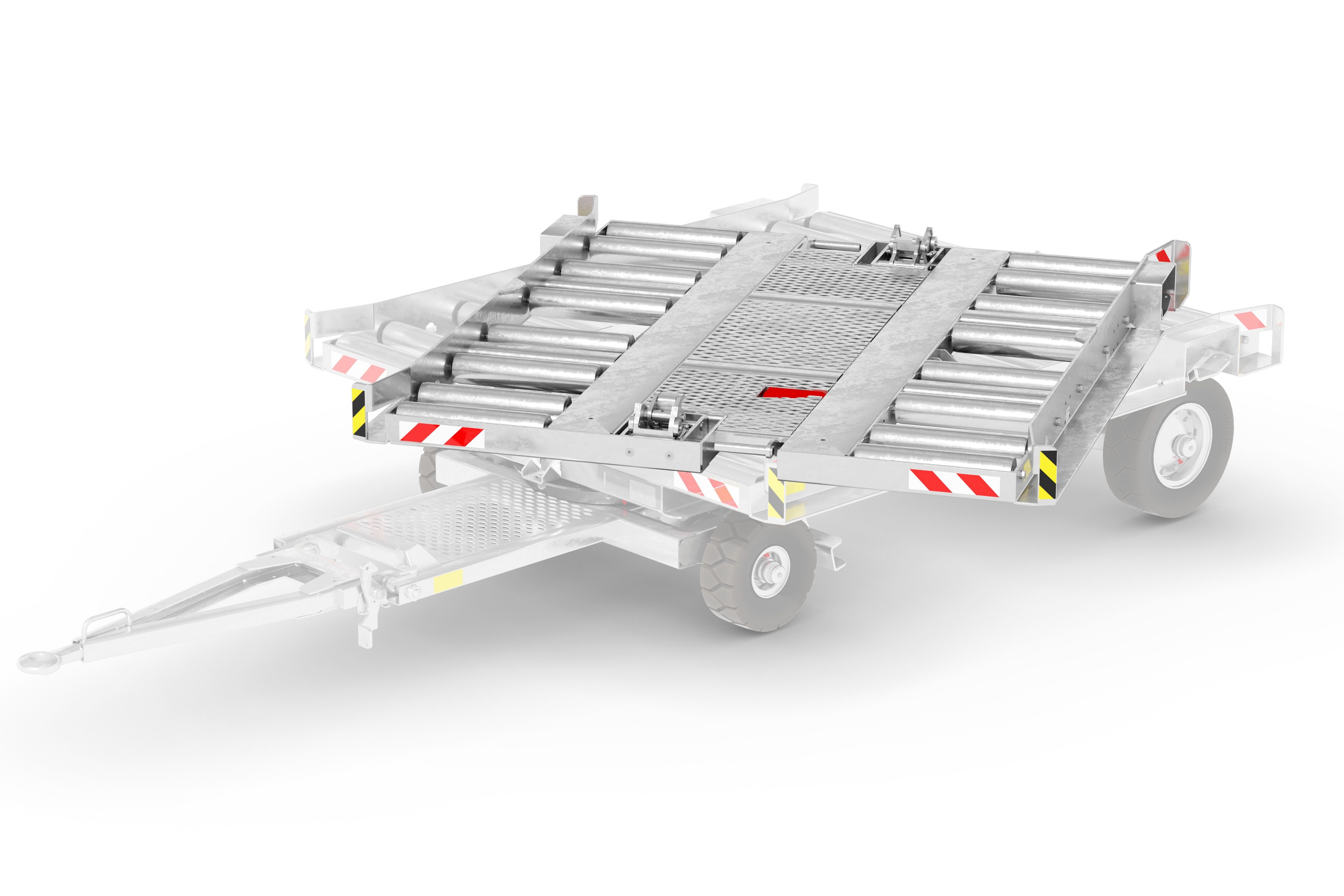

We developed a unique running gear system for the KCT7000 dollies, that combines the advantages of several existing solutions on the market, while eliminating their disadvantages at the same time. Independent free-swivelling front axles mounted on individual turntables provide excellent manoeuvring properties while preserving the uncompromised stability, whereby the problematic coupling of a fixed towbar is solved by its ability to temporarily swing aside with an automatic locking back in the straight position. The result being an even easier and safer handling without the risk of bending and destroying the towbar. The parking brake reliably stops all four wheels of the fixed rear axle using balance bars. Container / pallet stops are centrally operated by handles located on the front and the rear end of the dolly.

To solve the transportation problem of such a large dolly, we designed foldable side sections of the frame, so that its folded width fits into a standard lorry or a shipping container.

For the need of an automated container / pallet handling using a special transporter vehicle, we also developed a dolly version with “fingers” on its right side, by which the transporter can connect with the dolly and easily load or unload a container / pallet. The stops in these “fingers” are controlled either automatically by the transporter, or manually using a foot pedal. These “fingers” too are foldable to assure easier dolly transportation.

|

Options:

All stops on the same level are operated together by one handle - either from the front or the rear side of the dolly.

All stops on the same level are operated together by one handle - either from the front or the rear side of the dolly.

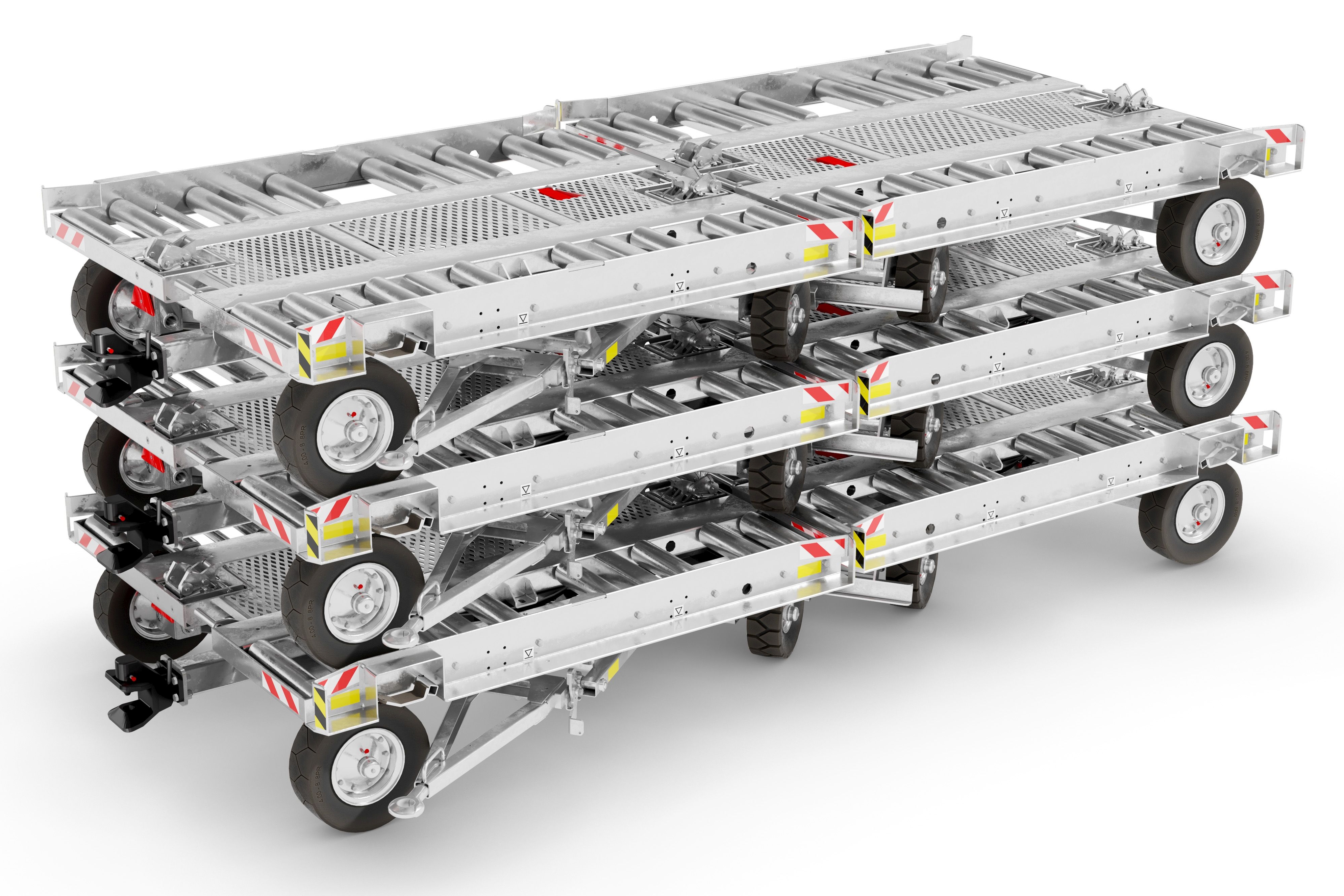

To enable a simpler and more cost effective transport by standard lorry or shipping container, the dolly's side segments have been made foldable. The subsequent assembly after unfolding is just a matter of tightening four simple bolts.

To enable a simpler and more cost effective transport by standard lorry or shipping container, the dolly's side segments have been made foldable. The subsequent assembly after unfolding is just a matter of tightening four simple bolts.

In addition to standard braking by raising the towbar, the brake is - for enhanced security - also activated in the case when unhitched towbar is lowered to the ground by its own weight.

In addition to standard braking by raising the towbar, the brake is - for enhanced security - also activated in the case when unhitched towbar is lowered to the ground by its own weight.